Contact

info(@)lightforminc.com

LightForm, Inc.,

825C Merrimon Ave., Suite 351

Asheville NC 28804 USA

Copyright 2024 © LightForm, Inc. All rights reserved

Detects microplastic particles and fibers ranging in

size from 1-micron to millimeters in milliseconds

Detects and Classifies Microplastic Part

icles and Fibers:

• Sample origin: Marine, lakes, rivers, sediment, wastewater, sanitation… • Discriminates against organics and sediment • Microplastic size: From 1 micron to millimeters to meet current environmental concerns • Speed of analysis: Typically less than 100-milliseconds. Average sample throughput between 50 to 80 samples per hour. Each FOV can contain an unlimited number of particlesSample preparation: Often little to none

Works with colored microplastics: Works with all colors - including

black.

Microplastics that can be detected:

Almost all including Polyethylene, Acrylics, Carbonates, Polyvinyl Chloride,

Polystyrene…•

Includes those that are stained and/or filled during manufacture.

•

Note:ColSpec detects, but does not identify the polymers present

in microplastic candidates.

Sample mounting:

• Typically, up to 47-mm filter membranes . • Includes X, Y, and Z sample translation with reference scalesColSpec Eliminates Nile Red and Fluorescence

• Eliminates staining, noxious chemicals, incubation, lasers, • No waiting to run a sample. Works in the field or laboratoryIdeal ColSpec users: Understaffed, budget strapped, State, Federal,

University, laboratories.

Detects microplastics based on darkfield, color-spectral,

imaging (CSI)

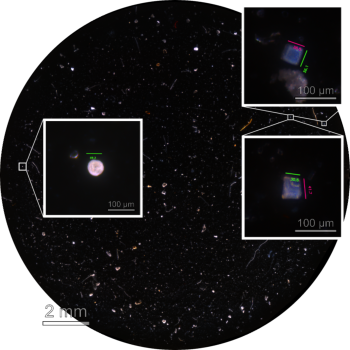

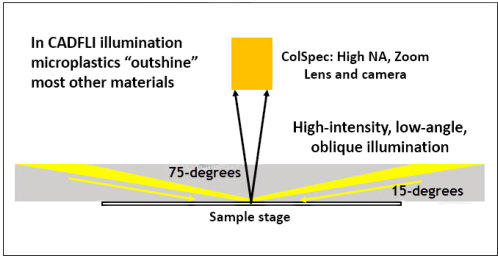

• CSI is a cousin of hyperspectral imaging. • Color-spectral imaging replaces an imaging spectrometer with a high-end color camera, that records the characteristics of objects in HSV color-space • HSV: Hue, Saturation, and Value: where “Value = Brightness.” the critical component missing from “RGB” • For detailed technical information on “color-space” go hereHow CSI in Critical Angle Darkfield Illumination (CADFLI)

works:

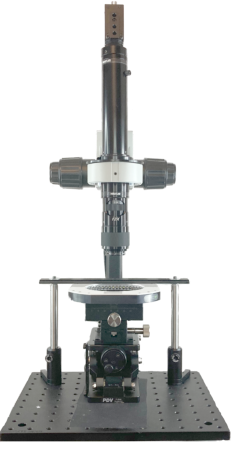

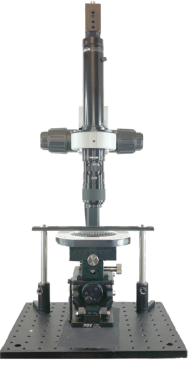

• High-intensity (40,000 lumen) illumination works in darkfield reflection strikes objects at angles greater than 75-degrees • At angles greater than or equal to 75-degrees, microplastics scatter light to reveal themselves as bright, high contrast, structurally detailed objects on a black or dark background • In contrast, weakly scattering non-plastic materials contribute to an overall dark background (see Figures B and C). • At non-zero angles of incidence, reflectivity and surface texture impacts HSV values to reveal structural detail not evident at normal incidence • ColSpec uses this information to deliver highly sensitive microplastic classification and characterization.ColSpec hardware includes:

• See Figure A • High numerical aperture zoom objective lens for variable magnification • High intensity, 40,000 lumen, CADFLI darkfield illuminator • Custom color camera acquires HSV color-spectra in darkfield reflectance • Sample translation stage • Optical breadboard base • 10” x 12” footprint • Works off 24V DC power supplyMicroplastic Color-Spectral libraries:

• Created using both supervised, and unsupervised learning • Object recognition libraries are based on the HSV values of either known microplastics or microplastics candidates • Each HSV reference library signature becomes a “class” that correlates with a particular object or plastic material Note: ColSpec detects, but does not identify the polymers present in microplastic candidates.

A. ColSpec MK2

Click and drag to enlarge

B. Sample taken from upper peat

layer, Biarritz, France.

Image courtesy of Oskar Hagelskjær,

Centre National de la Recherche

Scientifique (CNRS), France

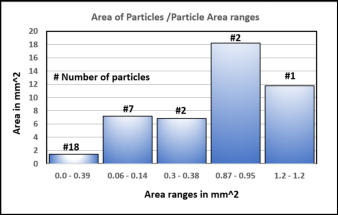

D. Histogram showing the area

occupied by particles

C. Mixed sub-millimeter microplastics

including clear, PET, with red and blue HDPE

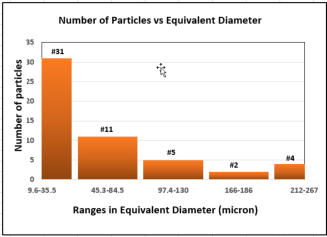

E. Histogram showing equivalent diameter

size ranges in the above image

Works with custom ColSpec software that includes:

Algorithms that are analogous to those used in hyperspectral imaging but in HSV color space that include: • Statistical analysis Percentages, areas occupied… • Object classification: plastic candidates are automatically assigned a class • Object recognition by class • Library creation: designated classes are entered into a library • Class abundance determination • Size and area distribution of recognized classes (Figures D and E) • Correlation algorithms with tolerancing • Data output numerical analysis in csv formatRelated technology – Darkfield Microscopy:

Darkfield imaging microscopy, in transmission, was first formally reviewed over one hundred years ago in the “Transactions of the American Microscopical Society Vol. 39, No. 2, Apr. 1920” For a detailed description of darkfield microscopy, see here hosted by Florida State University ColSpec applies the same principles of microscope-based darkfield transmission into darkfield reflection.ColSpec Pricing and usage: ColSpec is a portable, modular system right-priced for tight budgets

Bottom line: ColSpec detects microplastics in a wide variety of sample types with minimal if any sample preparation in

milliseconds.

ColSpec: An Optical Solution For Rapid, Non-destructive,

Microplastic Detection

Copyright 2024 © Lightform. Inc All rights reserved

ColSpec ®: Detects Environmental

Microplastics

ColSpec: Detects microplastic particles and

fibers ranging in size from 1-micron to

millimeters in milliseconds